1. Introduction

The Audi 5-cylinder 10V turbo engine is one of the most iconic powerplants in automotive history, especially revered by performance enthusiasts for its rally roots and unique engine note. But what keeps this mechanical legend performing at its best isn’t just forced induction or engine tuning—it’s also proper internal maintenance. One often overlooked yet crucial component in this process is the valve shim.

In this guide, we’ll explore Audi 5 cylinder 10v turbo valve shims—their role, how they affect engine health, and why understanding and maintaining them is vital for any Audi 10V turbo owner.

2. Understanding Valve Shims

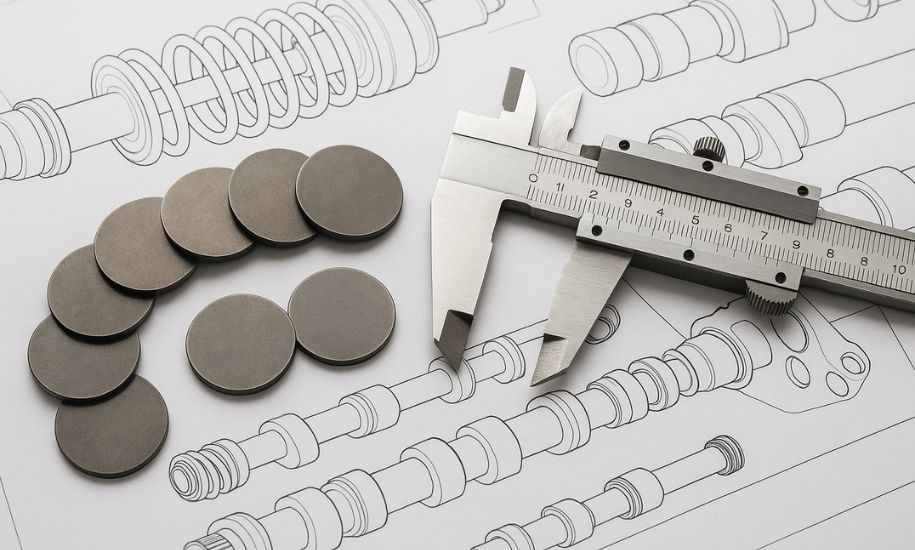

Valve shims are small metal discs used in engines with solid lifters or bucket-style cam followers. In the Audi 5-cylinder 10V turbo engine, they sit between the camshaft lobe and the valve tappet. Their primary purpose is to ensure correct valve clearance—the small gap that exists between the camshaft and the valve. This clearance is essential to allow for thermal expansion and to ensure the valves open and close properly.

If the clearance is too tight or too loose, it can result in performance loss, engine damage, or even total valve failure. Valve shims allow precise adjustment of this clearance without the need to replace the entire valve mechanism.

3. Importance of Proper Valve Clearance

Correct valve clearance is not just a technicality—it’s fundamental to engine function. When the clearance is too small, valves may not fully close, causing compression loss and overheating. If it’s too large, you’ll hear an audible ticking sound, and the valves won’t open fully, reducing efficiency.

Let’s look at what’s at stake if valve clearance is neglected:

| Issue | Result |

|---|---|

| Too Tight Clearance | Valve burning, compression loss |

| Too Loose Clearance | Noisy valvetrain, power loss |

| Incorrect Shim Size | Premature cam/lifter wear, valve damage |

Maintaining correct clearance with properly selected Audi 5 cylinder 10v turbo valve shims helps preserve both engine reliability and performance.

4. Symptoms of Incorrect Valve Clearance

Recognizing early warning signs can save you from expensive repairs. When the valve clearance is off, your engine will likely give one or more of the following symptoms:

- Tapping or Clicking Sounds: A classic indicator of excessive clearance. The ticking sound comes from increased space between the cam lobe and the shim.

- Loss of Engine Power: Poor valve timing means less efficient combustion, directly impacting power output.

- Misfires at Idle or Load: Inconsistent valve lift causes irregular firing cycles.

- Decreased Fuel Economy: An imbalanced engine uses more fuel to achieve the same performance.

- Increased Exhaust Emissions: Improper valve timing leads to incomplete fuel combustion.

If you notice any of these signs, it’s time to inspect your valve clearances and potentially replace your valve shims.

5. Tools and Equipment Needed

Adjusting valve shims isn’t a job for the unprepared. You’ll need the following tools to check and adjust the valve shims on your Audi 10V turbo:

- Feeler gauge set (metric sizes)

- Valve shim adjustment tool (specialty tool for shim removal)

- Micrometer or digital caliper (to measure shim thickness)

- Torque wrench (for retorquing camshaft caps)

- Clean workspace and gloves

- Replacement shim kit (multiple thickness options)

A proper shim kit usually includes multiple sizes, such as from 2.50 mm to 4.00 mm in 0.05 mm increments, to cover all potential needs.

6. Measuring Valve Clearance

Before you can adjust or replace any shims, you must accurately measure existing valve clearance. Here’s how:

- Rotate the Crankshaft: Align the cam lobe pointing away from the shim you are measuring.

- Insert the Feeler Gauge: Gently slide it between the cam lobe and shim.

- Find the Snug Fit: The gauge should fit tightly without force; this indicates the current clearance.

- Record the Measurements: Do this for each valve on both intake and exhaust sides.

Compare your results to the Audi service manual specifications, typically:

| Valve Type | Standard Clearance |

|---|---|

| Intake | 0.20 – 0.30 mm |

| Exhaust | 0.35 – 0.45 mm |

7. Calculating and Selecting the Correct Shim Size

Once you’ve measured the existing gap and compared it to the specs, it’s time to calculate what shim size you need. Use this formula:

New Shim Thickness = Current Shim Thickness + (Measured Clearance – Desired Clearance)

Example:

- Current shim = 3.25 mm

- Measured clearance = 0.45 mm

- Desired clearance = 0.30 mm

- Calculation = 3.25 + (0.45 – 0.30) = 3.40 mm

Replace the current shim with a 3.40 mm shim.

Use a precision micrometer to verify the thickness of any shim before installing it.

8. Replacing Valve Shims

Now for the part that requires the most patience: replacing the shims. Follow these steps:

- Remove the Valve Cover: Expose the camshaft and shims.

- Position the Cam Lobe Away: Rotate the engine to give you shim clearance.

- Use the Shim Tool: Depress the valve bucket and extract the old shim using tweezers or a magnetic pickup.

- Insert New Shim: Place the correctly measured replacement.

- Recheck Clearance: Confirm the clearance with the new shim in place.

- Repeat: Continue for each valve, and torque everything to spec afterward.

9. Maintenance Schedule and Best Practices

Audi recommends checking valve clearance every 40,000 to 60,000 miles, especially on performance-tuned or older turbo models. In practice, here are some key tips:

- Check Annually: If the vehicle is used for performance or spirited driving.

- After Engine Rebuild: Always recheck shims after significant internal work.

- Use a Shim Log: Track which shims are installed and when.

- Avoid Cheap Shim Kits: Precision matters—buy OEM or reputable aftermarket kits.

10. Upgrading to Performance Valve Shims

For those pushing their 10V turbo engines beyond factory specs, performance shims can provide better durability and tighter tolerances. High-performance shims are often made from hardened steel and may offer improved heat resistance.

Benefits Include:

- Reduced wear during high RPM use

- Consistent clearance over time

- Better fitment with performance camshafts

Choose performance shims if you’ve installed high-lift cams or run higher boost levels on your Audi 5-cylinder engine.

11. Common Issues and Troubleshooting

Even with careful measurements, things can go wrong. Here are typical problems and solutions:

| Problem | Likely Cause | Solution |

|---|---|---|

| Valve still noisy after shimming | Incorrect shim size or wear | Re-measure and replace |

| Engine misfire persists | Damaged valve or lifter | Inspect deeper mechanical issues |

| Shims popping out or rotating | Improper installation | Use correct installation tools |

If issues persist, it may be time to consult a performance mechanic with Audi 10V experience.

12. FAQs

Q1: Can I replace Audi 5 cylinder 10v turbo valve shims myself?

Yes, with patience, the right tools, and a workshop manual, DIY replacement is possible.

Q2: How often should valve shims be checked?

Every 40,000–60,000 miles, or sooner if performance changes are noticed.

Q3: Can incorrect valve clearance damage my turbo?

Not directly, but poor valve function can lead to detonation or misfires, harming the turbo system over time.

13. Conclusion

The performance and reliability of your Audi 5-cylinder 10V turbo engine depend heavily on proper valve clearance—something that only correctly sized valve shims can ensure. Whether you’re maintaining a stock classic or upgrading for performance, understanding Audi 5 cylinder 10v turbo valve shims is critical.

Routine checks, accurate measurements, and careful replacements will keep your engine running smoothly for many miles to come. Don’t overlook this vital aspect of your Audi’s internal health—it’s more important than most people think.

Other Articles

Fort Worth Mesothelioma Lawyer Vimeo: A Complete Legal Resource Guide

How to Calibrate Health o Meter Scale: A Complete and Easy-to-Follow Guide

How to Reset Health o Meter Scale: Full Guide for Accurate Readings

How Interior Design Affects Mental Health – A Complete Guide by MintpalDecor